COAtex

Innovative coatings – Coatings for many areas of application

The quality and optics of a plastic surface are affected by many parameters in the production process. New design trends can reach their limits caused by restrictions to tools or material. This is where the coatings from Eschmann Textures come into play: Improved filling ability optimise material, substance properties in production, higher wear resistance, longer service lives and ensure a constantly high quality – to ensure that your products stay in trend.

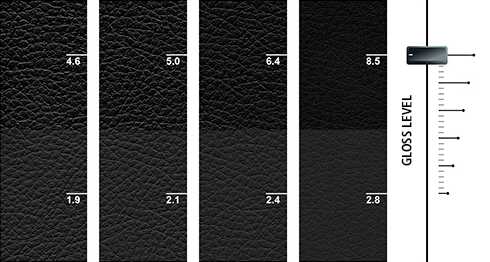

CERAmat and G-Coat are flexible coating processes. Both can significantly reduce shine to a nearly lacquer-like finish without changing the surface´s basic texture – flexible and a reasonable cost.

At a glance

G-Coat: improve injection and moulding issues, optimise surface finish

CERA-mat: gloss level Adjustment

CERA-coat: mechanically machinable flexible coating

Optimised injection moulding production

- Reduces process-related problems in the production of plastics such as “tiger striping”, gloss spots or micro-ghosting

- Can be used in combination with all standard plastic moulding steels and aluminium on chemically etched and/or lasered surface textures

- Especially for PP-based plastic substrate

Properties and Benefits

- original equipment or optimisation of virtually all tool dimensions

- short processing times

- suitable for low layer thicknesses and low draft angles

- low coating temperature means no thermal impairment of tool steel

- coatings can be flexibly adjusted to fit the requirements of plastics

- suitable for conventional cleaning agents and can easily be removed

Cost-saving innovation

- Ceramic-based coating technology with an extended range of applications

- Suitable for textured tool contours in order to supply small batch series

- Can be handled mechanically and allows flexible change management (e.g. milling, grinding, drilling)