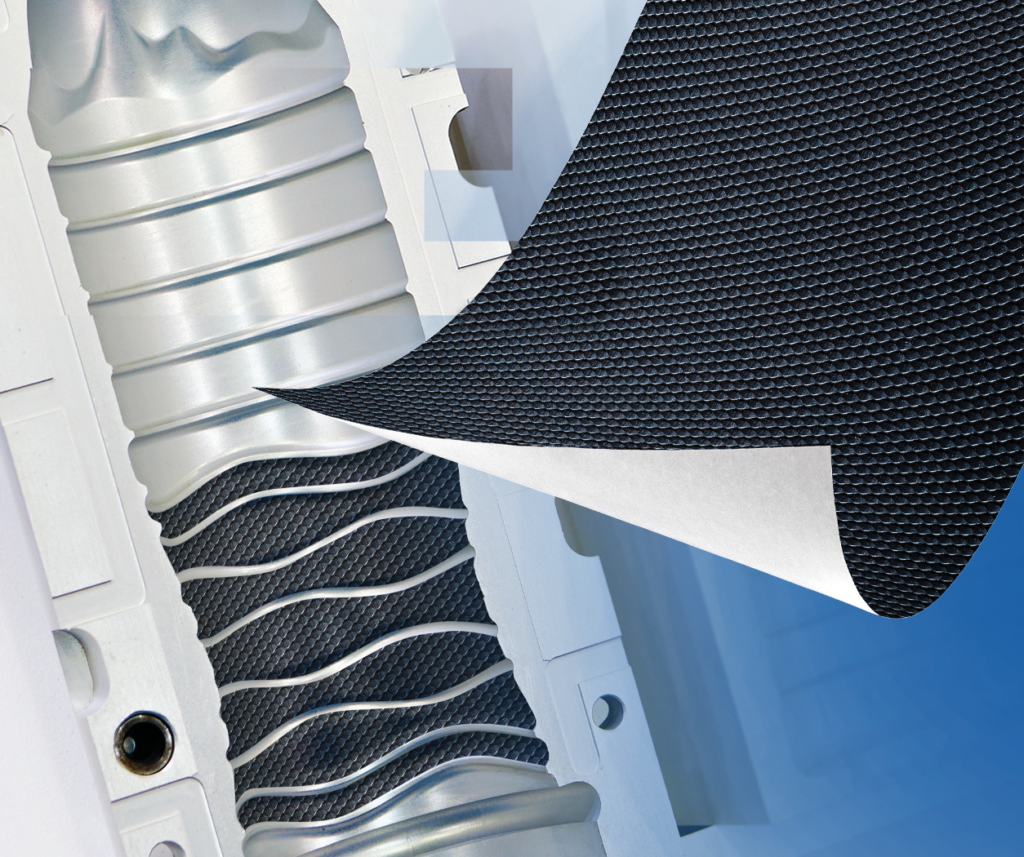

PROTOtex

Innovative 3D printing technology for pre-visualisation

FAST DEVELOPMENTS

PROTOtex at a glance

- Ideal for design review, models and show cars

- The texture can be transferred in 3D printing

to any material, e.g. plastic, model board and alloy - Unique process, providing a cost-effective way of bringing

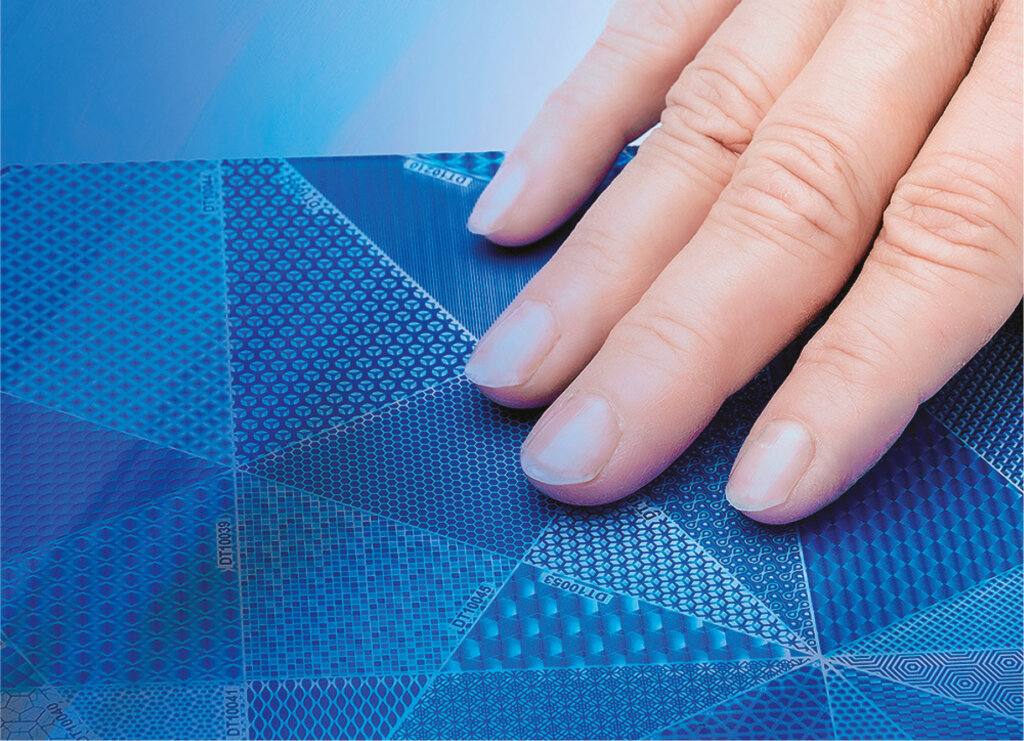

together colour and texture in a single tool - 3D textures can be applied to flexible, self-adhesive

decorative carriers - Virtually any design can be presented, even in multi-colour

We develop aesthetic and functional surfaces with cutting-edge graphics processing and can present them in plastic using 3D printing technology in a wide colour palette. Surface textures developed in a 3D printing process can also be transferred to components with a high degree of reproducibility with Eschmann Textures PROTOtex prototype modelling. For our customers this means a significant shortening of the decision-making process. Depending on the respective requirements for tool geometry and design, the appropriate technology can be selected for subsequent tool processing.

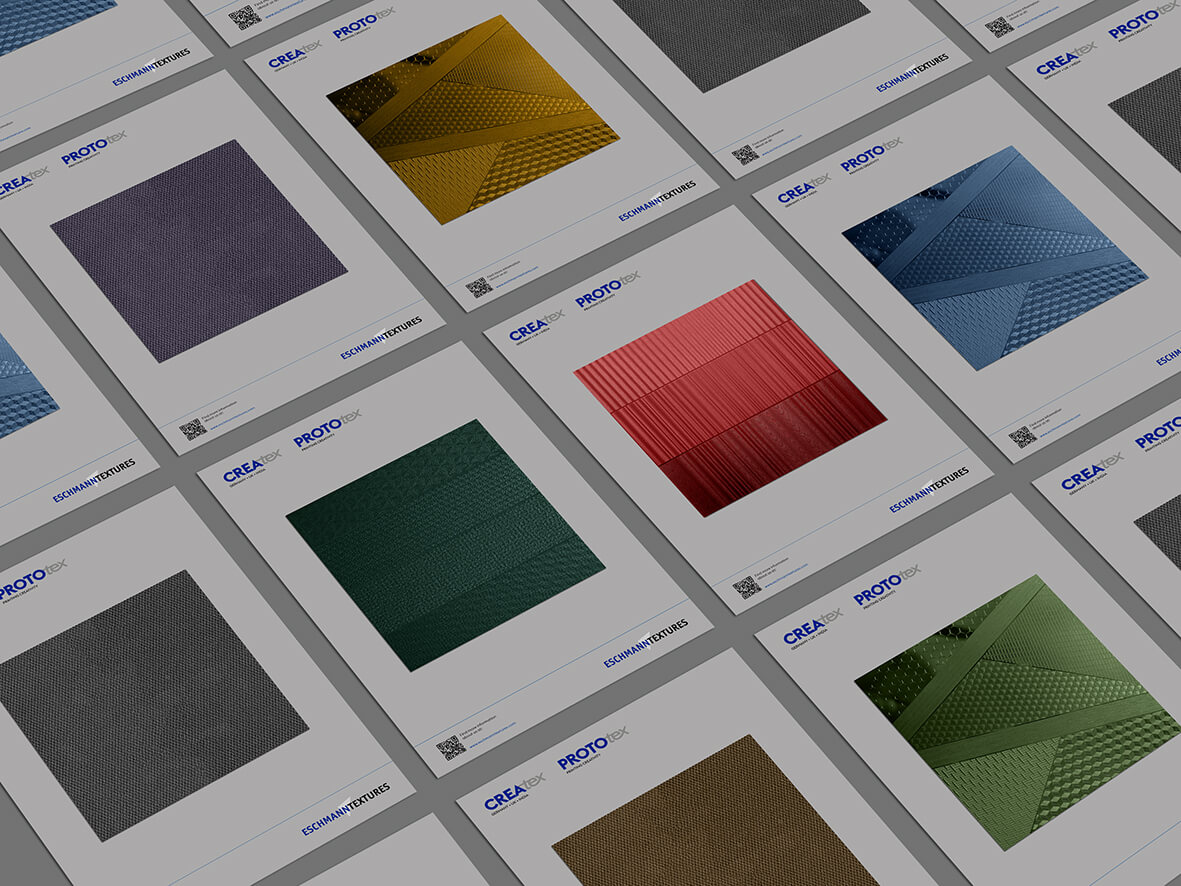

Visualising a range of designs

- Rapid development cycles

- Textures can be graphically designed by our design team in line with your ideas and modelled in 3D

- Cuts product development and decision-making processes substantially

- Can be painted to customer specifications, from matt to gloss, or impressing colours

Unique process

- Wrapping models and parts for design review or show cars

- 3D textures can be applied to flexible, self-adhesive decorative surfaces

- Particularly suitable for use in blow moulding

- Unique process offering a cost-effective way of bringing together colour and texture in one tool

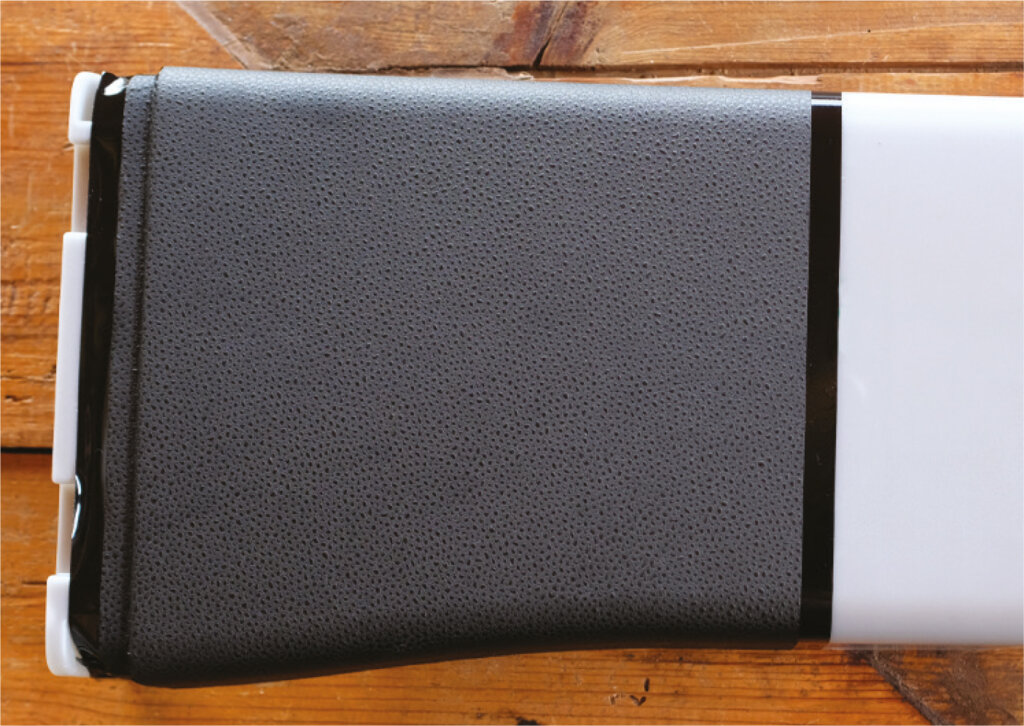

Part wrapping – Ideal for design review, models and show cars

Injection moulding – Flexible grained sheet that can be easily replaced with different designs

Blow moulding – Allow to obtain superior reproduction from the engraved texture surface on the mold

“Give expression to your ideas.”